Operating conditions and contact fluids

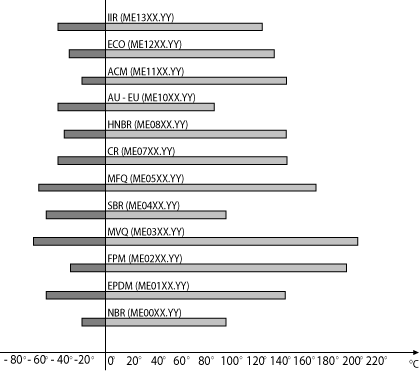

After having shown the principal characteristics of some of the most common compounds for O-Rings in the previous paragraph, we would now like to provide a summary that allows us to compare their behavioural characteristics at high temperatures and on contact with certain fluids. That graphs and tables that follow contain the results of tests that we have carried out on samples of the compounds that we commonly treat. In figure 8.1, we summarise the behaviour dependant on the temperature of some compounds. The tests were carried out in special circuits where the fluids to be contained had a high compatibility with the compounds under examination. The values shown are average values obtained from series of tests on the compounds with the most common composition. Elements may be added to each compound which improve the behaviour at extreme temperatures, enlarging the compatibility zones. For more information regarding the compounds and their various compositions please contact our technical office.

Figure 8.1

Figure 8.1

Table 8.3 shows the results obtained from the direct contact of certain elastic compounds with the fluids indicated.

The compatibility was evaluated on the basis of the physical variations and variations of volume that the sample underwent following contact. We have considered admissible an increase of volume equal to 10% of the initial value for dynamic seal applications, whilst for higher blowing values, up to 30% of the initial value, the compound is only considered suitable for static seal applications. For blowing percentage values close to 30% we have introduced the concept of probable static compatibility, as the test cycles that we have carried out did not have completely univocal results. For some of the crossings between fluids and compounds we were not able to establish the compatibility due to insufficient information, in such cases, no indication is shown in the corresponding cell.

Legend:

The last column of the table is reserved for the compounds that we advise to use for each fluid. However, these indications remain subordinate to the suitability of the compound for the effective work conditions.

The influence of fluids on elastomeric compounds does not only regard the blowing due to the formation of fluid sacs within the compound, but may also regard the solvent effect that the fluid can have on some components of the compound itself, such as, for example, the loads which are added to the base elastomer in order to confer to it particular chemical or physical characteristics. This effect expels the soluble element in the fluid from the compound and modifies the general behaviour of the elastomer. Therefore, it is not sufficient to immediately note the blowing percentage value of a compound to evaluate its compatibility with a fluid: its physical behaviour must also be analysed in order to evaluate whether or not the missing blowing is due to the replacement of the elements lost through dissolution with the formation of fluid sacs.

The compatibility was evaluated on the basis of the physical variations and variations of volume that the sample underwent following contact. We have considered admissible an increase of volume equal to 10% of the initial value for dynamic seal applications, whilst for higher blowing values, up to 30% of the initial value, the compound is only considered suitable for static seal applications. For blowing percentage values close to 30% we have introduced the concept of probable static compatibility, as the test cycles that we have carried out did not have completely univocal results. For some of the crossings between fluids and compounds we were not able to establish the compatibility due to insufficient information, in such cases, no indication is shown in the corresponding cell.

Legend:

- letter C: indicates complete compatibility with the fluid (blowing less than 10%);

- letter S: compatibility assured for static seal applications (blowing included between 10% and 30%);

- letter P: probable compatibility in static seals (blowing close to 30%);

- letter N: indicates non-compatibility between compound and fluid (blowing more than 30%).

The last column of the table is reserved for the compounds that we advise to use for each fluid. However, these indications remain subordinate to the suitability of the compound for the effective work conditions.

The influence of fluids on elastomeric compounds does not only regard the blowing due to the formation of fluid sacs within the compound, but may also regard the solvent effect that the fluid can have on some components of the compound itself, such as, for example, the loads which are added to the base elastomer in order to confer to it particular chemical or physical characteristics. This effect expels the soluble element in the fluid from the compound and modifies the general behaviour of the elastomer. Therefore, it is not sufficient to immediately note the blowing percentage value of a compound to evaluate its compatibility with a fluid: its physical behaviour must also be analysed in order to evaluate whether or not the missing blowing is due to the replacement of the elements lost through dissolution with the formation of fluid sacs.

Technical sheets