O Ring's seal

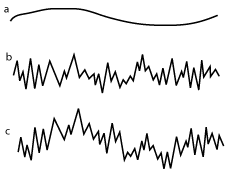

The O-Ring housing is based on the interaction between an elastic material ring and yielding, and ideally un-deformable surfaces which are pressed onto it. The housings that hold the O-Ring is part of the integrated seal system and its characteristics have a great influence on the system efficiency. The surface finishing of the O-Ring housings and of all the surfaces in which come into contact with it, are an important fact for the housing's capacity and for its life duration. The quality of a surface depends on the type of working and the level of finishing with which these are carried out. The dynamic seal systems must present precision and finishing levels higher than those of static seal due to the fact that the friction between parts accelerates the degrading of the O-Ring. The true profile observation shows the presence of two different types of surface imperfection: we have a "wave-like" imperfection (figure 4.1 – curve a) linked to the imprecision of the mechanical organ working, and an imperfection defined as "rugosity" (figure 4.1 – curve b) caused by the machines which intervene in direct contact with the surfaces. The surfaces in contact with the O-Ring present therefore some irregularity given by the sum of the imperfections described below (figure 4.1 – curve c).

Figure 4.1

Figure 4.1

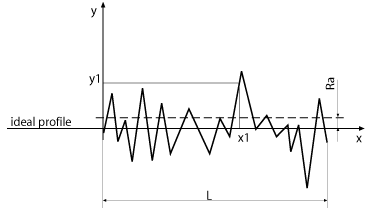

Our experience in the O-Ring sector has brought us to identify the parameters of recommended working to guarantee good seal performances and sufficient duration. In the following paragraphs we show the tables in which the recommended tolerance values are indicated to limit the negative effect of the waving and the maximum values of the rugosity Ra, in static and dynamic holding applications, recommended for the seal's surfaces and that of the support. The Ra parameter indicates the rugosity and is attained as an average level of rugosity, considering the absolute value, along a period of time defined as L (figure 4.2). In practice the reference previsions stabilise the period measure values L based on the particular's dimensions and the average rugosity Ra is measured as follows:

Ra = (1 / L) x %∫ y dx

where y is measured perpendicularly at the average surface profile in the length of period L.

Ra = (1 / L) x %∫ y dx

where y is measured perpendicularly at the average surface profile in the length of period L.

Figure 4.2

Figure 4.2

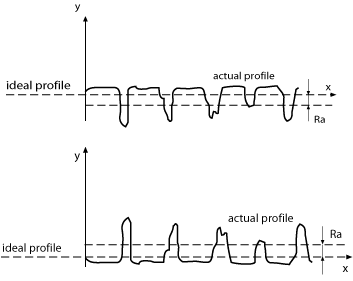

In reality, the Ra value can be a non indication of the quality of the housing to which represents the rugosity through an average of absolute values, bringing equal results also in cases in which the final effect may be very different. Actually, in figure 4.3 and in figure 4.4 two surfaces that present, if calculated, the same Ra value are represented. However, at the end of the housing, the behaviour could result in being very different. For this reason, we have imposed in the indication the Ra values as discriminate a bearing value of at least equal to 50% of the theoretic surface.

Figure 4.3 and Figure 4.4

Figure 4.3 and Figure 4.4

As a final consideration to the rugosity, we are able to add that the presence of crevices as of that in figure 4.3, could have a beneficial effect in dynamic holding case, because maintaining certain amount of fluid that can act as a lubricant reducing the friction between the O-Ring and the surfaces.