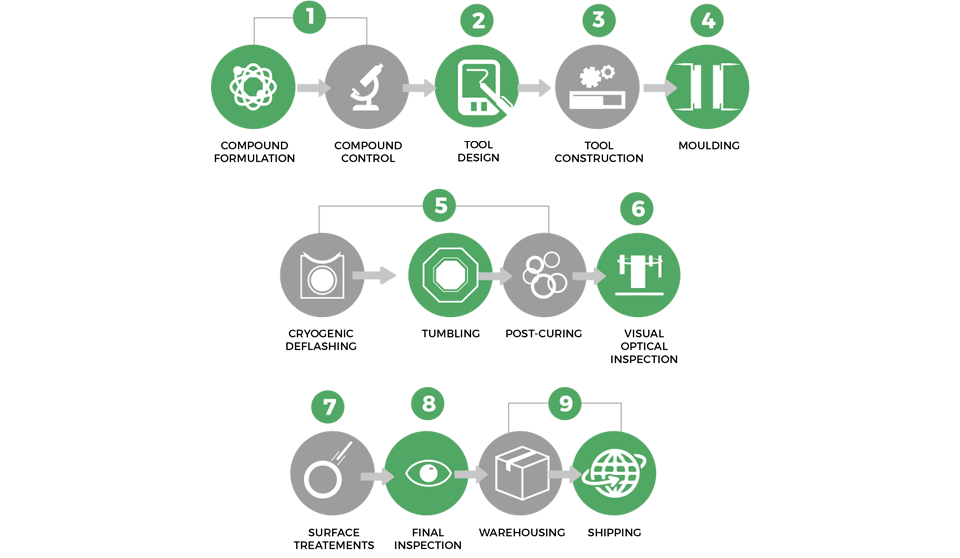

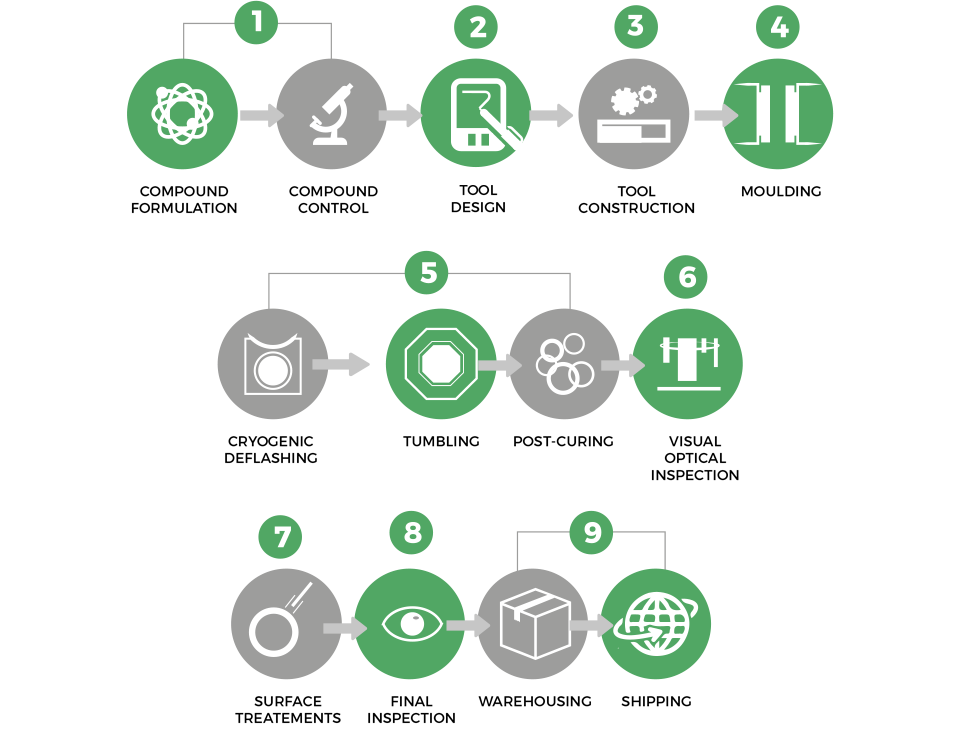

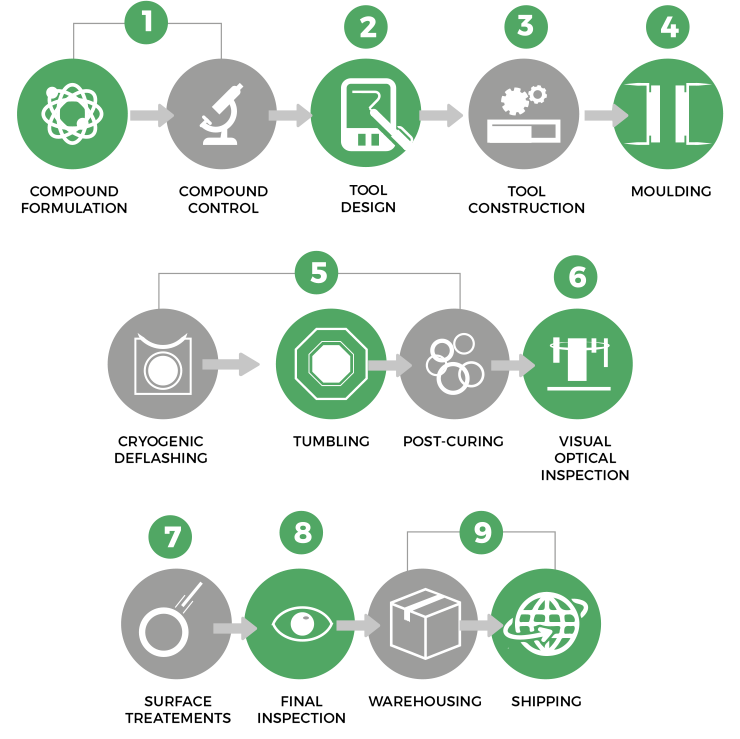

From raw material

to the end product

X

1. Laboratory

ET LAB is the beating heart of Elastotech. ET LAB is not just a laboratory, it is the place where the gasket project comes to life and where it is checked that the quality standards required by the customer are met.

Feasibility analysis, definition of the most suitable compound, design and implementation of technical drawing of the tooling, cost analysis and offer creation. These are the primary tasks carried out in the lab. But not only, ET LAB is a place of research and experimentation, of technological innovation to improve customer seals, create new ones, get us closer to the best possible production process. It is a future-oriented place, where data and statistics on internal processes are collected, new patents are studied, and knowledge is sought with the aim of making company resources grow. It is also a teaching place that allows the company to have a generational turnover for the work of tomorrow.

Feasibility analysis, definition of the most suitable compound, design and implementation of technical drawing of the tooling, cost analysis and offer creation. These are the primary tasks carried out in the lab. But not only, ET LAB is a place of research and experimentation, of technological innovation to improve customer seals, create new ones, get us closer to the best possible production process. It is a future-oriented place, where data and statistics on internal processes are collected, new patents are studied, and knowledge is sought with the aim of making company resources grow. It is also a teaching place that allows the company to have a generational turnover for the work of tomorrow.

X

2. Design

To design a gasket means conceive, work on the drawings, calculations and studies necessary for its realization. Once all the sensitive data has been received, the team analyzes the feasibility of the entire project: the use of the suitable compound, the creation and realization of the technical drawing of the tool, the simulation of the production process with the analysis of the costs that leads to the formulation of the offer.

ET LAB thanks to a concentration of devices, methodologies, knowledge and experience plans and programs the entire set of activities necessary to achieve the expected result.

ET LAB thanks to a concentration of devices, methodologies, knowledge and experience plans and programs the entire set of activities necessary to achieve the expected result.

X

3. Internal workshop

Our internal workshop, designs and produce molds for o-rings, washers and items in according to customer drawing with very complex geometries and tight tolerances. Our technical staff works together with our clients from the beginning of the projects, in order to find the best solution. This department is able to produce prototype tools in short time. The use of special steels and new alloys, with specific surface treatment as well as being an added value in terms of quality and reliability, allow Elastotech to work with any kind of raw material in full compliance with customer requirements.

X

4. Molding department

We use injection and compression molds, with molding technology at 4-8-16 and 32 nozzles and thermoregulated plates. Our presses have a tonnage ranging from 180 to 650 tons, which enable us to produce items with huge dimensions and consistent weight. We take care to the ordinary and extraordinary maintenance for the proper functioning of the presses, to ensure the highest quality standard required by our customers.

X

5. Finishing

Cryogenic deburring

During cryogenic blasting deburring, the components to be processed are subcooled in a processing room with a suitable coolant, and therefore the burrs become brittle, and are blasted with a blasting medium.

Tumbling

Tumbling is performed with special octagonal metal containers (called "tumblers"), water and stones (with various sizes); during the rotation, flashes are removed and the residues of molding from the pieces.

Vibrating screen

Special vibrating tables (vibrating screens), which allows to eliminate the aggregates remained and impurities.

During cryogenic blasting deburring, the components to be processed are subcooled in a processing room with a suitable coolant, and therefore the burrs become brittle, and are blasted with a blasting medium.

Tumbling

Tumbling is performed with special octagonal metal containers (called "tumblers"), water and stones (with various sizes); during the rotation, flashes are removed and the residues of molding from the pieces.

Vibrating screen

Special vibrating tables (vibrating screens), which allows to eliminate the aggregates remained and impurities.

X

6. Visual optical inspection

Each part is checked for dimensional and surface defects through a series of dedicated vision inspection stations. The acquired images are transferred to a computer for real-time image processing. The interaction with the operator is simple and intuitive thanks to the user-friendly interface.

Parts are sorted into different collection areas depending on the pass/fail criteria. Statistics and production times are available in real time, including number/type of defects and fill level of each collection area. It's also possible to save production reports with graphs and data for subsequent analysis.

Parts are sorted into different collection areas depending on the pass/fail criteria. Statistics and production times are available in real time, including number/type of defects and fill level of each collection area. It's also possible to save production reports with graphs and data for subsequent analysis.

X

7. Surface treatments

Coating treatment

PTFE, teflon coating for water contact certification, silicone coating, molycot treatment, talc treatment, plasma treatment.

High pressure washing

Washing machines with high pressure water jet system.

Type of treatment required from customer

We can offer dedicated surface treatment following the european food and water directive.

PTFE, teflon coating for water contact certification, silicone coating, molycot treatment, talc treatment, plasma treatment.

High pressure washing

Washing machines with high pressure water jet system.

Type of treatment required from customer

We can offer dedicated surface treatment following the european food and water directive.

X

8. Sorting department

Elastotech has a department dedicated to the 100% automatic sorting by the latest generation of artificial vision. The last upgrade allows us to inspect complex designed items. The ongoing research of advanced technologies enables us to ensure high quality performances at competitive prices.

X

9. Storage and packaging

Our warehouse ensure an optimal condition for the preservation of the material. With an increasingly demanding market, we have a stock of high rotating items certified by our quality system. This allows us to "support" the customer in case of an immediate request. We also guarantee a safety stock for customer who works with program orders, to better respond to sudden evolution of the market.

The packaging department has automatic packaging machines that allow the boxes containing the seals to be prepared quickly. They are able to process different sizes of items, from the smallest rubber item to the largest one.

The packaging department has automatic packaging machines that allow the boxes containing the seals to be prepared quickly. They are able to process different sizes of items, from the smallest rubber item to the largest one.