Equipment for the assembly of the O-Rings

To correctly carry out the assembly of the O-Rings it is advised that suitable equipment is used to avoid direct contact of the ring with all of the abrasive surfaces or that present a certain roughness. In the following figures, we show how to utilise such equipment in the case of O-Ring assembly for "cylinder seal" (figure 5.6) and in the case of "piston" seal (figure 5.7).

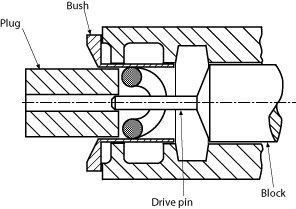

Figure 5.6

Figure 5.6Equipment for the insertion of the O-Ring for the cylinder seal

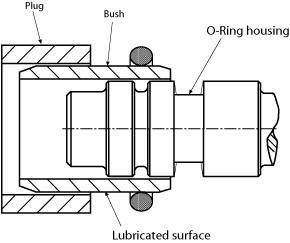

Figure 5.7

Figure 5.7Equipment for the insertion of the O-Ring for the piston seal

Cylinder seal: the plug pushes inside of the O-Ring element, which moves along inside a bush with smooth surfaces to avoid direct contact with the particular roughness; the drive pin has the job of ensuring that the ring positions itself correctly and the block prevents the O-Ring from going beyond the housing and uninstalling itself.

Piston seal: the O-Ring is threaded onto a bush that dilates the internal diameter allowing it to go over the irregular profiles of the piece; when the bush arrives in the proximity of the housing, the plug intervenes which pushes the O-Ring in the destination housing.

Piston seal: the O-Ring is threaded onto a bush that dilates the internal diameter allowing it to go over the irregular profiles of the piece; when the bush arrives in the proximity of the housing, the plug intervenes which pushes the O-Ring in the destination housing.