The role of the anti extrusion rings

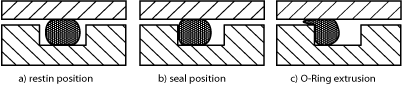

As analysed in the previous chapters, the O-Rings create the seal effect pressing against the housing parts that hold it. The capacity of the ensemble depend both on the correct choice of O-Ring (compound and dimension) and of the surface finishing of the housing and the play between the elements. When the O-Rings are called to exercise the seal in circuits in which the pressure reaches high levels, one of the risks to be considered is that of the ring extrusion from the housing. Such a risk is increased when the O-Ring mix is soft and the play between the parts is large. Figure 6.1 shows the extrusion process of an O-Ring from its housing.

Figure 6.1

Figure 6.1

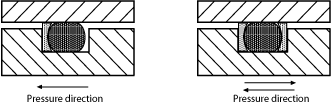

There are cases which exist where it is not economically viable to realise housings with finishing and play sufficiently reduced. To consent the role of the O-Ring, also in high pressure conditions, and where the working is not excessively accurate, we have realised the anti-extrusion ring, whose job it is to avoid the O-Ring from becoming extruded through the diametric play. The anti-extrusion rings are useful when the play between the parts is difficult to control or variable depending on the working conditions, and results particularly suitable in elements of large dimensions. In addition, their role allows the minimum reachable pressure inside the system without varying the type of O-Ring or the contact surface finishing. The anti-extrusion rings can be used individually or in pairs in cases in which the pressure on the O-Ring can be exercised in both directions (figure 6.2).

Figure 6.2

Figure 6.2

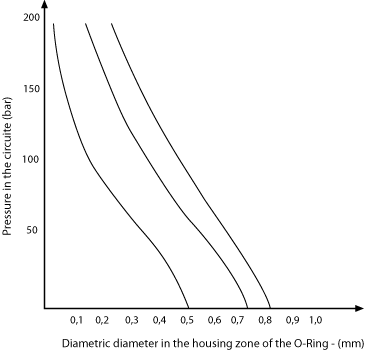

In the dynamic seal applications, the necessity of having ample relative diametrical play and the friction action between the O-Ring and the seal surfaces, increase the risk of extrusion. The presence of pulsing pressure in static seal roles imposes micro-shifting that can damage the surface and ease the extrusion. In the figure 6.3 diagram, the results attained subjecting a cyclic pulsing pressure test to various O-Ring compounds are carried forward. The compound samples tested were chosen with three different shore strength grades, in seal systems in which the diametric play between the elements was changed. The results attained showed that many compounds behaved similarly towards the extrusion possibility. The values shown were attained from an average of the experimental results and correspond to the behaviour of a wide range of different compounds. The only compounds that highlighted a behaviour which sensitively moves away from that shown in the figure, are the compounds with a silicon base, for which proved to extrude with greater ease.

Figure 6.3

Figure 6.3

For further information we beg you to contact our technical office.